INSTALLATION GUIDE

VEHICLE VINYL WRAP

PART ONE: Pre-Installation

Cleaning Products &Tools

- Grease and wax remover

- Generall Paint-safe Cleaner

- lsopropyl Alcohol (IPA)

- Lint-Free Towel or Lint-Free Paper Towel

- Squeegee

Application Conditions:

- Temperature:

Temperature plays a critical role in how weill the vinyl adheres to the substrate. We recommend a working temperature to be in the range under 21 C.

If the temperature is too low, there is a higher risk of tearing as the cold makes the film more brittle.

lf the temperature is too high, the adhesive will activate and bond more aggressively, this will add difficulty when repositioning the vinyl on the target surface - Environment:

We strictly recommend applying film indoors, as this will not only help maintain aconsistent temperature, it will also reduce the amount of dust and contaminants that may collect on the surface. - Vinyl Storage:

When storing vinyl, try not to expose the film to heat sources (radiators, heaters)or direct sunlight. Keep humidity as low as possible and always store the vinyl vertically

Before applying any film to a surface, the surface must be properly prepared and cleaned in the correct conditions or else the film may not adhere properly and you may run the risk of having bubbles and bumps appear on the surface.

Procedure:

- The first step is to clean the surface with paint-safe grease and wax remover to remove any dirt orgrime on the surface.We recommend to have the car generally cleaned with car wash soap (avoidusing cleaners with waxes).Then proceed to rinse the surface with water.

- Thoroughly dry the surface with a clean lint-free towel or lint-free paper towel. Pay particular attention to ridges, edges and seams as these areas are often neglected and may carry the most dirt and grime.To clean hard to reach edges, wrap a lint-free towel over a squeegee and proceed to swipe multiple times.Each swipe should be done with a clean portion of the towel until the towel shows no dirt on the swiped edge.This may be time consuming, but often these edges,especially in vehicle wrapping installations, are where the ends of the film are anchored and may peel off if not properly cleaned.

- Surfaces with any grease, oil or wax greatly reduce film adhesion and may form bubbles on neglected areas.To remove these contaminants, we recommend using a grease and wax cleaner.Alcohol-based cleaners, such as isopropyl alcohol may be used, but is not as effective at removing wax in comparison to solvent-based cleaners. Alcohol is best used for spot cleaning and a quick wipe-down.

- Make sure the substrate is completely dry before applying the film. If necessary, use a blow dryeror heat gun to speed up the process.

- Proceed to apply the film as soon as possible to reduce the amount of dust and contaminants thatmay accumulate on the surface over time.

"Some surfaces may react harshly to various chemicals. Be sure to research which chemicals can be used on the given surface.

PART TWO: lnstallation

Application Products & Tools

- Squeegee w/ felt tip

- Heat gun

- Utility knife

- 3M 94 Tape Primer

- WrapCut Fine Filament Edge Cutting Tape

- Cotton gloves

- Masking tape

- Tape measure

- lnfrared thermometer (optional)

Standard Films (Dry Application Method)

Applying vinyl takes practice, skill and most of all patience.For large projects, like vehicle wrap installations,we recommend having a second set of hands.

Placement

- Plan your method of attack. We recommend applying the film to flatter areas first, just becausethese tend to be simpler and more convenient to get out of the way.

- Check to make sure there is nothing hindering your application, such as logos, hood ornaments, and other bulky objects that won't be wrapped. We recommend researching how these objects stick to the car and the best method of removal.

- Using your tape measure, roughly measure the surface of the panel you are applying to, leaving extra material (at least 4-6 inches) on either side.

- Unroll the desired amount of film and cut using a utility knife.Try not to unroll or place the film on the floor, as this will leave dust and debris on the film, causing scratches when applying with a squeegee.

- With someone helping you, carefully remove the backing paper while applying some tension to the film, so that less creases appear. Have that person help you position the vinyl and drape the film over the panel. At this point, ensure that the entire panel is covered without any edges of the panel exposed.

- When placing vinyl on moderately curved surfaces, carefully reposition the vinyl in order to create tension over the entire surface.

*If you notice any creases or crumples after placement, just gently run a heat gun over the affected area to bring the vinyl back to its original form.

Application Procedure

- Visually identify the center of the panel.This will be your starting point.

- At the center work your up. After, move to the left or right of the center; work your way up and then down.

- Continue this process, as if you are dividing the panel in sections. After every completed section,move over to the next, untilyou reach the edge.

- For perfectly flat surfaces, DO NOTheat the film prior to installation. This will make the installation very tedious and time consuming. Just simply lay the film over the surface and complete the surface by working in sections, working from the center out,as described above.

- When using a squeegee, try applying using the felt tipped edge, as this will reduce the chance ofdamaging the surface of textured or glossy films.

- Use a firm, even pressure while tilting the squeegee on an angle (approx.45% tothe surface).

- Inch by inch, use a firm fluid motion while overlapping with already applied areas

- Make sure not to miss any areas. Even areas that are untouched yet look propermay still harbor air, every inch has to be pressured onto the surface.

- While applying over the surface, always examine and follow the most efficient route for the air totravel beneath the vinyl.

- On curved surfaces, you will inevitably encounter some folds or creases on the film.Reposition the filmas tight as possible and flash heat on areas not touching the surface to add extra tension.

- ltis critical not to overheat the film. This can lead to losing the texture or luster of the film, changing the color or burning holes in the film.

- Every film has a different tolerance to heat and we suggest testing how much heatthe material can tolerate before application.

- While still pliable, carefully apply tension to the film and work your way through the area using yoursqueegee or gloves. Do not work the film when it's too hot or you risk damaging the film.

- At one point, these folds or creases slowly transition into what's known as “"crow's feet'". lf you chop atthese, they will flatten and become wrinkles.To get rid of crow's feet, cup the small creases, one at atime, until they reduce in size or disappear.

- lf this is not enough, lift the film to encompass the area with the crow's feetand proceed to heat over this general area.

- Using both hands carefully pull the film until the vinyl appears flat. While still applying tension lay the film over the surface.

- Try to squeegee the remaining crow's feet and if they still do not disappearrepeat steps 7.i to 7.iii untilthe crow's feet eventually disappear.

"For standard chrome films we recommend applying another layer of laminate over the film because the finish may fade due to the metal particles reacting with sunlight. Supercast chrome is already pre-laminated.

Properly finishing the installation can make the surface seem as if it was never vinyl wrapped in the first place. Making this seamless finish requires experience, skill and most importantly,paying close attention to detail. Improper finishing can lead to revealing the surface beneath, poorly sealed edges which slowly peels over time.

- Edges:

Edges refers to the space between two panels of the surface. For example: on a car, it would refer to the space between the front door and a fender.

To prepare this area, gently heat the space between the two panels and run your finger down the gap while wearing cotton gloves. This will help cure the adhesive over the edges of the gap and will also help conceal the surface beneath. Continue this process over all seams on the surface.

- Wheels:

Great attention must be done to properly seal the area around the wheels because these areas are most exposed to contaminants and abrasion.Heat the edge around the tire and run your finger along the circumference one inch at a time.Once you've done one pass over, repeat this process multiple times until the edge in completely covered all the way to the back.

At one point, running your finger over the circumference will cause a lot of tension over the vinyl and will become difficult to push in.To relieve this tension , cut slits below the area, as shown in the figure.

The final product should extend all the way back to the edge of the area above the tire.Heat over this area once more and add pressure to further cure the glue to create a stronger adhesive bond with the edge.

- Cutting:

Cutting requires a sharp blade or you will risk tearing the vinyl as appose to slicing it. Also, cutting takes very steady hands and intricacy or you may run the risk of cutting the surface and damaging it.

Now that we are detailing the wheel, we will begin to cut this area.Just simply run the blade along the inside edge at a 45 degree angle.Make sure that you feel the side of the safely glide along the body panel.

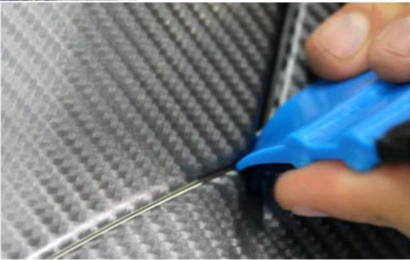

Next, we will proceed to cut the area between two panels. Place the tip of the blade over the flat edge of your squeegee. Make sure to have a firm grip on both the blade and the squeegee so that they stay in place.While exposing only 1-2 millimeters of the blade, run this blade/squeegee along the gaps.This ensures that you do not damage the paint, keeps a consistent gap and pushes the vinyl firmly over the edge.

This method of slicing is our favorite, it delivers a consistent slice,the added 2-3 mm adds enough overlay to tuck the film between panels.

- Corners:

For rounded or sharp edge corners, heat the vinyl until malleable and push the film deep in the corner crevice.A moderate amount of heat should be used on the corner in order to fuse the area. Do not cut when film is still hot.

- Post Heating:

Our XPO generation of vinyls are mainly heat activated. Basically our films are designed to be easily repositionable (low tack) before the vinyl is heated and adheres firmly (high tack) after the vinyl is heated. Once the wrap is finally complete, set your heat gun to the highest setting and run it over the entire surface. Some neglected areas may harbor air, so just simply squeegee the air out using the most efficient path.

- Edge Priming:

Edge priming is basically applying adhesive primer to a surface before it is wrapped. Basically priming an edge is not a permanent solution. It is only to be used for tacking a film down or changing the surface energy of an edge. We recommend post heating all primered areas for a lasting bond.

- Edge Sealing:

Edge sealer is basically transparent liquid tape that strengthens the edges of the vinyl after it is applied to the surface.Edge sealer should be used when the area in which the vinyl is installed will be subject to chemicals, moisture and other contaminants. Such as, marine applications, areas near the fuel cap, wheel wells, etc..

PART THREE: Post-installation

Cleaning & Care

- After the surface has been wrapped, let it sit in room temperature for 24 hours. This will allow the glue to properly cure.

- Do not wash the car for at least 3-4 days in order to avoid any contact with chemicals that may hinder the curing process.

- When cleaning matte or textured films, avoid using soaps with any traces of wax or protectants as these may damage the finish.

- When using pressure washers, make sure the nozzle is at least 24 inches away from the surface, is kept lower than 2000 psi and water is below 80 degrees Celsius.

- Do not run your car through an automatic car wash as you do not have any control over the type of soap being used or the pressure applied. Brush type car washes can ft wrapped edges and dull

- out the texture of the film. We recommend hand washing your vehicle or surface just to be safe.

- Lighter or white vinyls are generally harder to clean. If you do encounter a hard to remove blotch or discoloration, we recommend using a vinyl safe cleaner. Do not rub too hard.

- To remove difficult contaminants, such as bird droppings or bug splatter, try soaking these areas in hot soapy water for several minutes, then rinse and dry.

- Fuel spills can be especially harsh to paint as well as vinyl wrapped surfaces. If you manage to spill fuel on the surface, wipe it off immediately to prevent any damage or discoloration.

- Just like paint, vinyl wrap continually gets degraded due to the sun's harmful UV rays. Exposing your wrapped vehicle to the sun may lead to faded color or texture over the years. Even though it may take a while before noticing the sun's effects on the vinyl, we recommend storing your vehicle indoors or covering it with a protector. Storing your vehicle indoors or covering it will also prevent rain, hail or dew, which contains acidic pollutant, to contact the vinyl surface

"Before applying any sort of chemical, read the label and ensure that it is suitable for vinyl. The general rule of thumb is you should not apply anything that you would not apply to paint. Also, all chrome red vinyls from all manufacturers, seem to discolor the most and the fastest. For these, we recommend laminating it to prevent discoloralion.

PART FOUR: Removal

Removing vinyl thankfully takes much less time than installing it. Usually, the longer the vinyl has been on the surface, the stronger it bonds to the surface and the more difficult it is to remove.This is due to the fact that the glue had much more time to cure on the surface.

The best strategy for removing vinyl wrap is to make sure that you are indoors in a relatively warm area (about room temperature). lf you are in cold conditions, the vinyl will become brittle and will crack when trying to peel it off. Simply take your heat gun, grab a corner of the installed area and slowly with a generous amount of heat, pull the vinyl off. lf you notice that pulling off the vinyl creates a crackling sound or pulls off in tiny increments, the vinyl is not hot enough for removal.

COMPRIMISED PAINTED SURFACES:

When a vehicle has been damaged with vinyl on the surface or paint that was originally questionable prior to the wrap.lt is rare, but we've seen instances with vinyl removing paint on poorly re-painted surfaces or damaged areas. Removing the film will take a lot more work and patience. With light pressure, run the blade down the film ( make sure the blade does not go through the film) and crease out the vinyl in smaller sections. Heat the vinyl and slowly pull the film away.

Another issue during removal is glue residue. When using adhesive promoters and primers, chances are, it will leave adhesive residue when film is removed.This will not damage the painted surface or compromise the quality of the surface. lt is simply a small annoyance that can be rubbed off with your finger or removed with adhesive removing solvent ( make sure you are using a paint-safe solvent)

0 Comments